High Standards of Quality Certified by Authorities

2020 Newest PVC Membrane Foil

The best designs PVC foil for your furniture, doors, kitchen cabinets, wardrobes, wall claddings…

Get Free E-catalog Now

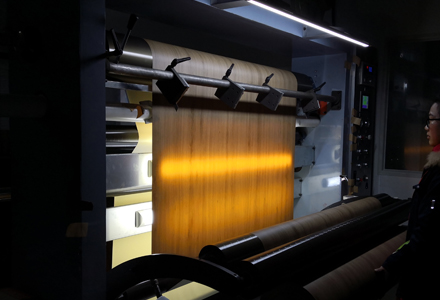

A Video Tour to Our Factory

- Calendering, printing, laminating integrated factory, to provide you stable quality foil.

- Over 25 years experience in PVC film industry, to offer you best advices.

- Big production capacity, to give you delivery time warranty.

- 600+ popular colors, be free to choose.

- Strong technical and research team, to develop unique product for you.

- Quick response, fast sampling, short time delivery, to save your time cost.

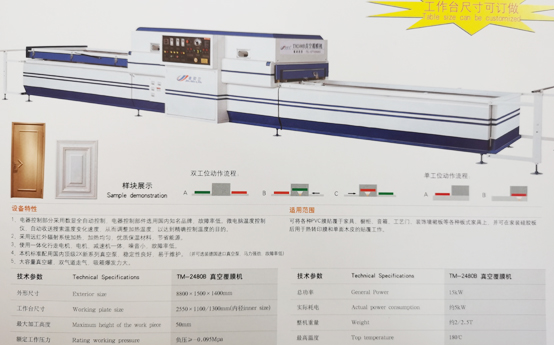

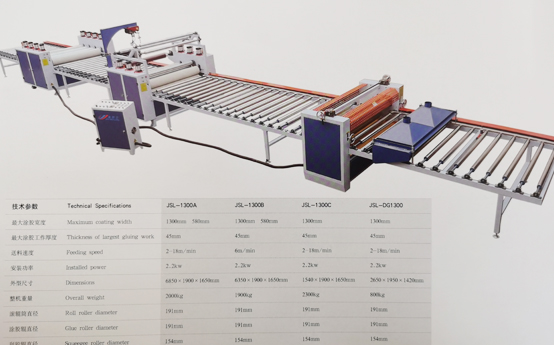

How To Process

Working Temperature: 13o℃ – 170℃

PVC Film Thickness: 0.16mm – 0.5mm

Working Temperature: normal

PVC Film Thickness: 0.12mm – 0.5mm

Working Temperature: normal

PVC Film Thickness: 0.12mm – 0.28mm

Working Temperature: 125℃ -170℃

PVC Film Thickness: 0.12mm – 0.5mm

FAQ’s

To make an order of PVC membrane foil from B-TRUST, please help to provide below information that will help us to learn your needs.

1. Please advise where do you want to use the PVC membrane foil?

- The applications normally are: for vacuum pressing on MDF panels to make kitchen cabinets, doors.

- For cold laminating on plywood panel/particle board/steel panel/orgional wood panel.

- For wrapping on aluminum profile/pvc profile/wpc profile/wood profile.

- For hot pressing on other material like TPR/ACRYLIC etc.

Which one is the same in your case?

2. Are you new for this product or no? Please advise the size of PVC membrane foil?

- We will recommend you the size of PVC membrane foil to use if you are new.

- Please advise the thickness and width of PVC membrane foil you are using now.

- The standard size we provide is: 0.12-0.6mm thick, 1260mm/1400mm/1430mm wide.

- Special sizes please confirm with us before placing order.

3. Can you provide us more technical details to help us learn your needs?

- The working temperature is different from machines and foil softness. Please help to provide your working temperature to help us match proper PVC membrane foil that works the best on your machine.

- Different usage environment also has different requirements on PVC membrane foil. Please advise us the environment temperature that your products will stay. If it’s very hot or extremely cold? It will help us to produce the proper environment resistance PVC membrane foil for you.

4. Choose color and confirm order quantity.

- You can choose colors from our catalogs, and we also welcome your customized colors.

- We normally have an MOQ of 2000 meters/color, if you couldn’t reach MOQ for the first order, there is still possibility to talk about.

Here we will take over the rest, and you will only need to wait order delivery!

To calculate how many meters we can load in one 20ft container, there are only 3 simple steps!

- Our standard packing size for one roll is 260x260x1400mm, and weight 80kgs.

- One pallet size is 1100x1100x1450mm, and 16 rolls/pallet.

- One 20ft container can load 10 pallets+90 rolls.

Here you will calculate the loading container quantity very easy. Below you will also find our roll meters for different thick PVC membrane film.

- 0.35x1400mm 110m/roll

- 0.3x1400mm 130m/roll

- 0.18x1400mm 200m/roll

- 0.2x1400mm 200m/roll

- 0.12x1400mm 500m/roll

1. Is your PVC foil in real thickness or fake thickness?

We know that PVC foil prices are different from thickness, but have you ever think about if your PVC foil is in real thickness or in fake thickness?

What is real thickness? – The real thickness means that the raw material thickness of PVC foil.

What is fake thickness? – The fake thickness means that the final embossed PVC decorative foil thickness.

So what is the difference? For example:

You bought PVC decorative foil in thickness 0.35mm, and this PVC decorative foil is a deep embossed type. Now you will measure the foil by thickness gauge. It measures 0.35mm thick. Is it the real thickness? No, it’s the fake thickness. Because if the raw material PVC foil is 0.35mm, after embossed it will become thicker.

Now you know why suppliers give you such different prices? One reason is because of real thickness and fake thickness.

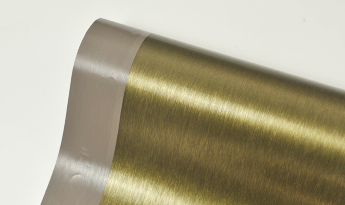

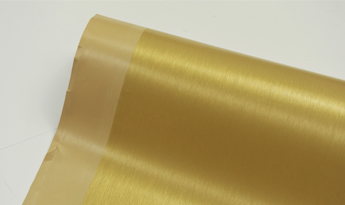

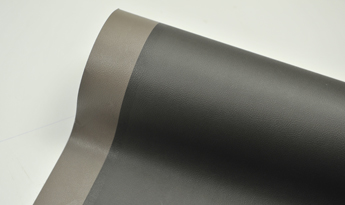

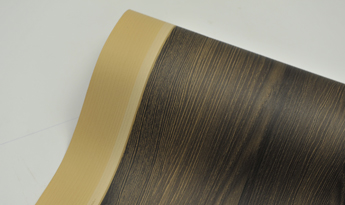

2. Is your PVC foil showing “white edge” after folded?

When you order PVC membrane foil for doors, and use it for vacuum pressing. Imagine after the process, the groove edge surface turns to white color, and your door is in dark color, the white edge totally ruin your complete door! How frastrated you are!

This is the “white edge” we say. The white edge is caused by PVC foil raw material defect. It will not only cause the white edge, but also makes the PVC foil very fragile to break when you stock it and use it.

The most simple way to check before order is : folding the sample PVC foil, and see if there is white edge.